Packaging machinery

Depending on the type of food and also the type of packaging requested, the appropriate equipment can be procured to achieve production goals in the food industry.

Packaging machinery categories

Solaris Smart3D

The SOLARIS EVO is a new High Speed Continuous motion vertical form fill and seal wrapper that produces 3-side sealed pillow-bags, block bottom and steelo bags, Doy-style also with zip and eurohole.

R-700

The R700 is a very compact and innovative machine that allows very quick format changes. It features unique technical solutions which include the film reel holder shaft positioned on the side of the machine body instead of the traditional rear position; the introduction of the self-centring film tracking unit positioned on the top of the frame that guides the film towards the forming tube and the drastic reduction in the number of idle film rollers that transfer less inertial energy to the film allowing for greater acceleration.

BG 2800

The BG 2800-4800 produces flow pack packages with three seals that have a perfect appearance. Designed for High Speed packaging, in MAP as well, with completely air tight seals, compact, smooth, free from product wrinkles and of the highest quality for when the package appearance is of the highest importance.

D400 EPT

The D400 EPT is a unique and revolutionary machine because it features an EPT conveyor with magnetic carriages: in other words, each carriage is mechanically separated from the others and therefore moves independently.

The magnetic EPT, after its length is properly set, allows to group multiples of pouches in the dosing zone, thus doubling the time available for such operation. This function results to be very useful when the dosing time (that is, the time needed to fill the pouch) is a limiting and binding aspect.

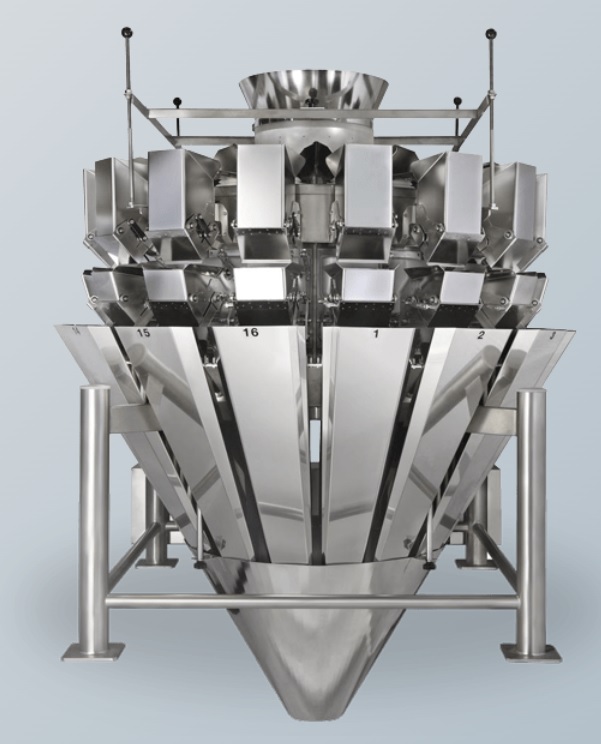

MBP C2 Series

Designed for high-speed, high-precision weighing of various types of granular products, the Series C2 is the fruit of 20 years’ research, development and design work. The outstanding speed/accuracy ratio ensures greater savings and operating safety.

X-Ray food inspection machine

Food X-ray machine with maximum capacity of 1500 g and dimensions up to 200 x 100 mm.

An innovative solution that combines high-level inspection of X-ray systems, a restrained cost and the possibility of integrating an internal weighing system interior.

X-Ray food inspection machine

X-ray inspection for food products with a maximum capacity of 5000 g and dimensions up to 235 x 150 mm.

Top-level solution to inspect packaged products. At the highest level in terms of performances, longevity, safety and design, it presides with the maximum effectiveness the critical control points and is the best guarantee for the protection of your brand.

Combined Checkweigher with X-Ray system

Combined Checkweigher + X-ray, equipped with touch-screen panel, for small-medium format products of any type, even with metal film or aluminum foil.

The best of inspection technology, integrated with the best-selling Italian checkweigher in the world.

The product is first inspected by a top-level X-ray system; if the check does not detect contaminants, the product continues its path on the weighing plate, where its weight conformity is checked.

The group has all the advanced features of both the checkweigher and the X-ray, thus guaranteeing the product's compliance with the restrictive parameters set by the European Directives (MID) and by market standards (BRC, Marks & Spencer, etc.).